Indicative Projects

NANOLEFINS

Ανάπτυξη Καινοτόμων Νανο-καταλυτικών Υλικών και Αντιδραστήρων για την Αποδοτική και Εκλεκτική Υδρογόνωση του CO2 προς ελαφρές Ολεφίνες

![]()

Source of Funding: Εθνικού Σχεδίου Ανάκαμψης και Ανθεκτικότητας «Ελλάδα 2.0» με τη χρηματοδότηση της Ευρωπαϊκής Ένωσης – NextGenerationEU (κωδικός έργου: ΤΑΕΔΚ-06169).

Duration: 2022- 2024

Partners:

-

Πανεπιστήμιο Δυτικής Μακεδονίας (ΠΔΜ)

-

Πολυτεχνείο Κρήτης (ΠΚ)

-

Αριστοτέλειο Πανεπιστήμιο Θεσσαλονίκης (ΑΠΘ)

-

Ίδρυμα Τεχνολογίας και Έρευνας (ΙΤΕ)

-

Ανώνυμη Εταιρεία Βιομηχανικής Έρευνας, Τεχνολογικής Ανάπτυξης & Εργαστηριακών Δοκιμών, Πιστοποίησης και Ποιότητας (ΕΒΕΤΑΜ Α.Ε.)

-

ΕΛΒΙΟ Α.Ε. ΣΥΣΤΗΜΑΤΩΝ ΠΑΡΑΓΩΓΗΣ ΥΔΡΟΓΟΝΟΥ & ΕΝΕΡΓΕΙΑΣ

Research area: -

![]()

Αντικείμενο: Το ερευνητικό έργο NANOLEFINS αποσκοπεί στην συνεργιστική αλληλεπίδραση μεταξύ των συμμετεχόντων ακαδημαϊκών (ΠΔΜ, ΠΚ, ΑΠΘ), ερευνητικών (ΙΤΕ) και βιομηχανικών φορέων (ΕΛΒΙΟ, ΕΒΕΤΑΜ) με εκτεταμένη εμπειρία και τεχνογνωσία στους τομείς της σύνθεσης/χαρακτηρισμού/αξιολόγησης καινοτόμων (νανο)υλικών (ΠΔΜ, ΠΚ, ΑΠΘ, ΙΤΕ), της ανάπτυξης δομημένων καταλυτών βιομηχανικής πρακτικής (ΕΒΕΤΑΜ) και του σχεδιασμού/ανάπτυξης εμπορικής κλίμακας καταλυτικών αντιδραστήρων (ΕΛΒΙΟ) προς την κατεύθυνση του επιτυχούς σχεδιασμού καινοτόμων καταλυτικών συστημάτων ενεργοποίησης του CO2.

Επιστημονικοί και τεχνολογικοί στόχοι του έργου NANOLEFINS:

(α) Ο σχεδιασμός, η ανάπτυξη και η αξιολόγηση πολυ-λειτουργικών καταλυτών με υψηλή ενεργότητα (≥50% μετατροπή CO2), εκλεκτικότητα (≥ 60% σε ολεφίνες) και ανθεκτικότητα (≥ 100 h), για την υδρογόνωση του CO2 προς ολεφίνες.

(β) Η χρήση κατάλληλων μεθόδων σύνθεσης καταλυτών χαμηλού κόστους οι οποίες θα επιτρέπουν την επίτευξη της επιθυμητής μορφολογίας, δομής και επιφανειακής χημείας του καταλύτη, ως προς τη μεγιστοποίηση της παραγωγής ολεφινών και τον περιορισμό των ανεπιθύμητων αντιδράσεων.

(γ) Η ανάπτυξη δομημένων καταλυτικών συστημάτων (μονόλιθοι, πελέτες) υψηλής μηχανικής αντοχής και χαμηλής πτώσης πίεσης με βάση τα βέλτιστα νανοϋλικά.

(δ) Η ανάπτυξη πιλοτικής μονάδας/αντιδραστήρα υδρογόνωσης του CO2 προς ελαφρές ολεφίνες

(ε) Η εκπόνηση τεχνικοοικονομικής μελέτης και ανάλυση του κύκλου ζωής της συνδυασμένης ολοκληρωμένης διεργασίας

NANOCO2 project

Rational design and development of nano-structured catalysts for CO2 hydrogenation to value-added products (NANOCO2)

![]()

Project Code: Τ1ΕΔΚ-00094

Starting day: 04/06/2018

End day: 03/06/2021

Project coordinator: Ass. Prof. M. Konsolakis, Technical University of Crete, Greece

Partners:

- Technical University of Crete, Laboratory of Industrial, Energy & Environmental Systems

- Centre for Research and Technology-Hellas (CERTH)

- HELBIO S.A. HYDROGEN AND ENERGY PRODUCTION SYSTEMS

- Materials Industrial Research & Technology Center S.A.

Short description: The present proposal aims to develop a green catalytic process using CO2 as a chemical building block towards valuable chemicals (methanol, syngas, methane). In particular, novel, noble-metals free, metal oxides will be tailored on their architecture and nanostructure as well as their macrostructure in order to facilitate the design and development of a RES-derived CO2 hydrogenation process.

Project objectives:

- Synthesis of nano-structured materials of specific architecture/functionalization towards CO2 hydrogenation

- Development of highly active, selective and durable materials for CO2 hydrogenation under mild reaction conditions (Τ< 400 oC, P< 10 bar)

- Development of structure catalysts (monoliths, pellets) of high mechanical endurance (>20 MPa), porous structure (>40%) and low pressure drop.

- Pilot plant reactor design and development (x50 lab scale)

Work Packages (WP):

- WP1 (M01-M18): Synthesis and characterization of nanomaterials

- WP2 (M16-M36): Catalytic/mechanistic evaluation studies

- WP3 (M16-M36): Pilot plant studies

Indicative publications:

- Michalis Konsolakis, “The role of Copper-Ceria interactions in Catalysis Science: Recent Theoretical and Experimental Advances”, Review Article, Applied Catalysis B: Environmental 198 (2016) 49-66.

- A. Vourros, I. Garagounis, V. Kyriakou, S.A.C. Carabineiro, F.J. Maldonado-Hódar, G.E. Marnellos and M. Konsolakis, “Carbon Dioxide Hydrogenation over Supported Au nanoparticles: Effect of the support”, Journal of CO2 Utilization 19 (2017) 247-256.

- V. Kyriakou, A. Vourros, I. Garagounis, S.A.C. Carabineiro, F.J. Maldonado-Hódar, G.E. Marnellos and M. Konsolakis, “Highly Active and Stable TiO2-Supported Au Nanoparticles for CO2 reduction”, Catalysis Communications 98 (2017) 52-56.

- J. Díez-Ramírez, P. Sánchez, V. Kyriakou, S. Zafeiratos, G.E. Marnellos, M. Konsolakis, F. Dorado, “Effect of support nature on the cobalt-catalyzed CO2 hydrogenation”, Journal of CO2 Utilization 21 (2017) 562-571.

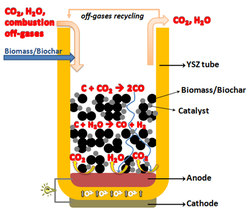

DB-SOFC project

Direct Conversion of Biomass to Electricity in MED area via an Internal Catalytic Gasification Solid Oxide Fuel Cell

![]()

Operational Program : ERANETMED2-72-246

Duration: 2017 – 2020

Partners:

- Greece-University of Western Macedonia

- Italy-Politecnico di Torino

- Germany-Karlsruhe Institute of Technology

- Spain-National Institute of Coal

- Turkey-Yildiz Technical University

- Cyprus-University of Cyprus

- Morocco-Mohammed VI Polytechnic UniversityUniversity of Western Macedonia

Project coordinator: Ass. Prof. M. Konsolakis, Technical University of Crete, Greece

![]()

Short description:

Biomass is a renewable energy source that is abundant in Euro-Mediterranean (EURO-MED) area. In particular, Spain, Italy, Greece, Turkey, Morocco, participating-among others (German, Cyprus)-in the present consortium hold more than 85% of the word’s olive production, cultivating at the same time large areas with grape vines. In view of this fact, there is a huge biomass potential regarding olive kernel and pruning from olive oil and grape vine cultures. In addition, these EURO-MED countries are still behind the current progress toward energy exploitation of municipal solid waste (MSW). In the light of the above aspects, the proposed project aims at developing an environmentally friendly and highly efficient process for the direct valorization of solid carbonaceous materials of low added value (e.g. biomass) and of particular importance for the EURO-MED area, namely: agricultural residues from olive and grape vines cultures and the organic fraction of urban waste, in a Solid Oxide Fuel Cell (SOFC) system, aided by an internal catalytic gasification process, towards electricity generation. To overcome the anodic kinetic restrictions derived from the limited contact between solid carbon and electrolyte/solid anode, a novel approach is proposed based on the in situ catalytic gasification of biomass to gaseous products and their consequent electro-oxidation at the anode surface.

CASANNO Project

Development on novel catalyst composites via the synergy of structural and surface promoters for the simultaneous abatement of nitrogen (ΝΟx) and nitrous (Ν2Ο) oxides

![]()

Source of Funding: European Union and Greek national funds through

Operational Program "Education and Lifelong Learning" of the National Strategic Reference Framework (NSRF)-Research Funding Program: THALES

Duration: 2011 – 2015

Partners:

- University of Western Macedonia (UoWM)

- Technical University of Crete (TUC)

- Center for Research & Technology Hellas (CERTH)

Research Area: Environmental Catalysis

![]()

Short Description:

Nitrogen (NOx) and nitrous (N2O) oxides abatement is a subject of considerable environmental interest, since both contribute to a variety of environmental problems (Global Warbing, stratospheric ozone depletion, acid rain, photochemical smog). In this regard, the simultaneous abatement of NOx and N2O emissions, consist a challenging issue in the area of environmental catalysis.

The present project aims to develop highly effective catalytic materials, able to simultaneously control NOx and N2O emissions. Multifunctional materials of novel architecture are adopted to achieve this goal. The desired catalytic properties are expected to be tuned by combining the appropriate synthesis procedure with the simultaneous use of promoters.

From fundamental research viewpoint, the present project aims to gain insight into the mode of action of structural/surface promoters on the area of heterogeneous catalysis. In this context, advanced characterization techniques (XRD, XPS, SEM/EDS, TEM, DRIFT, FTIR, TPR/TPD) are employed to achieve the structure-activity correlation.

Role in the Project:

Physicochemical characterization of catalysts

The physicochemical properties of the as prepared materials are determined by means of various characterization techniques. The total surface area (BET), pore size distribution (PSD) and dispersion (D) of active phase are revealed by means of physisorption and chemisorption techniques. Moreover, the structural and morphological characteristics of the as prepared materials are determined by means of X-ray diffraction (XRD) and scanning electron microscopy (SEM).

Probing structural and surface properties by means of advanced characterization technique (structure-activity correlation)

State of the art characterization techniques are used to systematically elucidate the role of promoters on the structural, morphological and surface properties of the as prepared materials, i.e.:

- X-ray photoelectron spectroscopy (XPS)/ Extended X-ray Absorption Fine Structure (EXAFS) to probe the local structure and chemistry in the noble metal and promoter species immediate environment .

- High Resolution Scanning Transmission Electron Microscopy (HR-STEM)/Electron Energy Loss Spectroscopy (EELS) to study the structure and chemical properties of promoted samples at nano-scale level.

- DRIFT/FTIR spectroscopy to reveal the effect of promoters on surface chemistry.

- Temperature Programmed Desorption (TPD) to investigate the effect of promoters on the reducibility and the chemisorption ability of the as prepared materials.

- Thermogravimetric analysis (TGA-DTA/DSC) to investigate the thermal behavior of samples.

DCFC Project

Efficient conversion of coal to electricity – Direct Coal Fuel Cells (DCFC)

http://dcfc.wp.st-andrews.ac.uk/

![]()

Source of Funding: European Union-FP7/RFCS

Duration: 2011 – 2014

Partners:

- University of St Andrews, Scotland

- Instituto Nacional del Carbon, INCAR-CSIC, Spain

- Technical University of Denmark, DTU

- University of Western Macedonia, Greece

Research area: Clean Coal Technologies-Electocatalysis

![]()

Short description:

The worldwide growing energy demand cannot only be compensated by the renewable energy sources. Moreover, hydrogen energy market is at an early stage, notably hampered by the high production, storage and distribution costs. On the other hand, coal is by far the most abundant and economic fossil fuel resource, covering more than 25% of the world’s energy consumption. However, its low energy conversion efficiency attained in conventional coal-fired plants along with the vast amount of greenhouse gas emissions, are major drawbacks towards the effective conversion of coal to energy. In this regard, the utilization of carbon with an environmental friendly and highly effective manner is of paramount importance. This is exactly the ultimate target of the present proposal, which aims at developing Direct Carbon Solid Oxide Fuel Cells (DC-SOFC) to directly exploit the chemical energy in solid carbonaceous materials with high fuel utilization and energy efficiency. To overcome the anodic kinetic restrictions derived from the limited contact between solid carbon and solid electrolyte/solid anode, a novel approach is proposed based on the internal (in situ) catalytic gasification of carbon to gaseous products and their consequent electro-oxidation at the anode surface.

Role in the Project:

- Development of effective electro-catalysts toward fuel cell performance enhancement

- Addressing optimization of composite anode/catalyst structures for efficient operation in both direct carbon oxidation and indirect CO oxidation modes.

- Impact of catalyst and/or carbonate slurry on fuel viscosity and ion transport properties

- Effect of feedstock physicochemical characteristics on fuel cell performance

- Interpretation of characterization results (SEM, XRD, FTIR, TGA, XPS), establishing a close structure-performance correlation

- Research planning/results dissemination

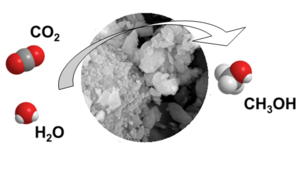

Green MEOH Project

CO2 and H2O toward methanol synthesis at atmospheric pressure in co-ionic electrochemical membrane reactors

![]()

Source of Funding: FP7 ERA-Net project CAPITA

Duration: 2013 – 2015

Partners:

University of Castilla-La-Mancha (UCLM)

Chemical Process & Energy Resources Institute (CPERI)/Centre for Research & Technology Hellas (CERTH)

Van’t Hoff Institute for Molecular Sciences/University of Amsterdam

Technological Educational Institute of Sterea Ellada-School of Technological Applications

Hellenic Petroleum Renewable Energy Sources S.A. (HELPE RES)

GRAPHENANO NANOTECNOLOGIES (Spain)

FeyeCon Carbon Dioxide Technologies (Netherlands)

Research area: Innovative catalysis for the monetization of low value carbon

![]()

Short description:

Methanol synthesis at atmospheric pressure from CO2 and H2O through a novel electrochemically-assisted process is proposed. The development of highly active and stable electro-catalysts as well as the fundamental understanding of their physicochemical characteristics is a challenging issue toward the successful implementation of the current project. The anodic catalyst will be exposed to H2O, catalysed its electrolysis to protons (H+) and oxygen. The protons will be transferred electrochemically through a conducting membrane to the cathodic electrode-catalyst, where they will react with CO2 to form methanol. Simultaneously, the cathodic electro-catalyst will activate the C=O bond via electrochemical removal of O2- ions to the anode.

Role in the Project

Physicochemical characterization of catalysts for methanol synthesis

Interpretation of characterization results obtained by different techniques: temperature-programmed reduction and desorption (TPR-TPD), X-ray diffraction (XRD), BET method, Microscopy Techniques (SEM and TEM), chemisorption, ICP, etc., allowing the investigation of the morphology, chemical structure, composition and reducibility of the active species present in the catalyst formulation.

Analysis of the characterization results obtained by means of in situ spectroscopy and microscopy techniques toward understanding the underlying reaction mechanisms and optimizing the catalyst design.

Surface chemistry and mechanistic studies

Elucidation of the mechanism determines the activity, selectivity and stability of the most promising catalysts.

Interpretation of the characterization results obtained by FTIR of CO adsorption (to investigate the chemisorptive properties), pyridine adsorption (to determine the acidity), XPS (to explore the surface composition and active phases chemical state), in situ DRIFTS (to study the surface phenomena taking place during reaction).